The Electronic Design Automation (EDA) market has reached a pivotal moment. With the industry valued at approximately $14.12 billion in 2024 and projected to hit $28.75 billion by 2032 (a compound annual growth rate of 8.25%), choosing the right PCB design software has never been more critical. But here’s the reality: there’s no single “best” tool—only the best tool for your specific needs.

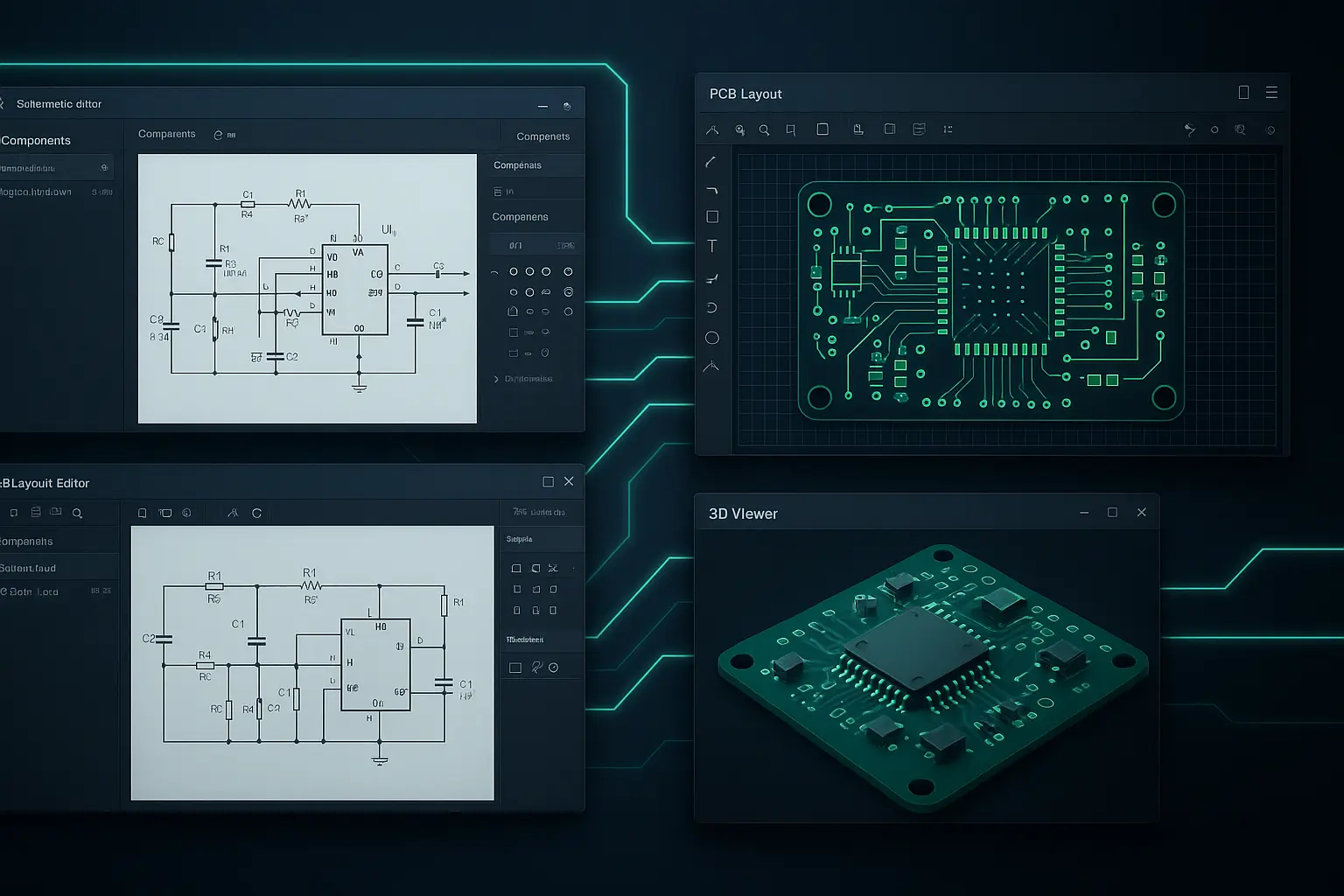

This complexity stems from an increasingly sophisticated electronics landscape where chip designs grow more intricate by the day, and miniaturized consumer electronics demand precision that traditional “draw and build” methods simply can’t deliver. Modern engineering requires a “simulate and validate” approach, where creating an accurate digital twin of your circuit becomes essential before committing to manufacturing.

Understanding the EDA Landscape: Three Distinct Tiers

The PCB design software market naturally divides into three capability tiers, each serving distinct engineering needs:

Tier 1: Enterprise Powerhouses — Altium, Cadence, and Siemens dominate this space. These platforms target large engineering teams working on high-reliability, high-density designs requiring the most advanced simulation capabilities. Think aerospace, telecommunications, semiconductor manufacturing, and automotive applications.

Tier 2: Integrated Professional Platforms — Tools like Autodesk Fusion 360 excel here, prioritizing seamless ECAD/MCAD integration. These solutions work brilliantly for teams where mechanical constraints matter as much as electrical performance—think consumer electronics, IoT devices, and wearable technology.

Tier 3: Open Source and Accessible Tools — KiCad leads this category, having evolved from hobbyist origins into a genuinely professional-grade platform. DipTrace and EasyEDA also compete here, offering various approaches to balancing capability with accessibility.

What Really Matters: Four Critical Evaluation Axes

When evaluating PCB design software, four fundamental criteria determine whether a tool will accelerate or hinder your workflow:

Design Flow Integration — How seamlessly do schematic capture, PCB layout, and library management work together? Switching between disconnected tools kills productivity and introduces errors.

Simulation Depth — Does the platform stop at basic circuit verification (SPICE), or does it extend into Signal Integrity (SI), Power Integrity (PI), and thermal analysis? Complex designs demand comprehensive physical validation.

ECAD/MCAD Integration — Can your electrical design communicate effectively with mechanical design tools? In modern product development, electronics don’t exist in isolation—they must fit perfectly within mechanical enclosures.

Ecosystem and Collaboration — Does the platform offer robust component libraries, active community support, and enterprise-level team collaboration features? These factors dramatically impact long-term productivity.

Enterprise Solutions: Maximum Power for Complex Challenges

Altium Designer: The Unified Productivity Platform

Altium Designer has established itself as the market leader for professional teams tackling high-reliability projects. Its core philosophy centers on bringing the entire design process—schematic capture, SPICE simulation, PCB layout, and manufacturing data management—into a single unified design environment. This approach eliminates the productivity drain of constantly moving data between separate applications.

Design Capabilities

Altium delivers what industry professionals call “unparalleled schematic capture” and “best-in-class interactive routing.” The platform handles advanced PCB technologies including rigid-flex designs and 3D-MID (Molded Interconnect Devices). Library management goes beyond basic component storage—tools like ActiveBOM provide real-time supply chain data directly within your design flow.

Simulation Strengths

At its core, Altium Designer features a sophisticated integrated SPICE simulation engine supporting PSpice, LTspice, and xSpice formats. The critical advantage? You can analyze circuits directly from the schematic editor without breaking your design flow.

The platform offers comprehensive SPICE analysis types:

- Transient (time-domain analysis)

- AC Sweep (frequency response)

- DC Sweep

- Noise Analysis

- Monte Carlo (analyzing component tolerance effects on performance)

- Parameter Sweep

Altium’s simulation strategy focuses on providing highly efficient validation tools integrated into the PCB designer’s daily workflow, rather than pursuing academic analysis depth for its own sake. This pragmatic approach maximizes engineer productivity.

Best For: Professional teams needing strong productivity tools, comprehensive component libraries, and reliable SPICE simulation without the complexity of enterprise-scale platforms.

Cadence: Scalable Power from OrCAD X to Allegro

Cadence approaches the market with a two-tiered strategy serving both mainstream professionals (OrCAD X) and top-tier enterprise needs (Allegro PCB Designer). This scalability represents one of Cadence’s most strategic advantages.

The Scalability Advantage

An engineer or team can start projects in OrCAD X and seamlessly transition to Allegro’s advanced analysis and team collaboration features as design complexity increases—more components, more layers, higher-speed signal requirements. Allegro excels at advanced 3D visualization and complex routing bundle organization.

Industry-Standard PSpice Simulation

Cadence’s simulation foundation is PSpice, considered the industry standard. PSpice integrates natively with OrCAD Capture (the schematic tool), making simulation critical both pre-layout (validating the design concept) and post-layout (identifying parasitic effects caused by physical routing).

PSpice comes with massive component libraries—over 35,000 verified models—and supports advanced analysis types including Monte Carlo, Sensitivity, and Smoke analysis (which examines power/voltage stress on components).

System-Level Co-Simulation

Cadence’s most distinctive simulation capability is SLPS (Simulink to PSpice Interface), which bridges PSpice with MathWorks’ MATLAB/Simulink platform. This co-simulation enables engineers to answer questions like: “How will this electrical circuit (in PSpice) behave when combined with control algorithms (in Simulink) as part of a complete mechatronic system (in MATLAB)?”

This isn’t just circuit simulation—it’s system simulation. Rather than treating circuits as isolated units, SLPS enables dynamic analysis as part of larger systems, making it critical for embedded systems, automotive, and power electronics applications.

Best For: Teams requiring scalable solutions that grow with project complexity, industry-standard simulation tools, and system-level modeling capabilities.

Siemens EDA: Enterprise Digital Twin Philosophy

Siemens (formerly Mentor Graphics) delivers the market’s most complex, high-performance, enterprise-focused solutions. Their strategy revolves around creating comprehensive “digital twins” spanning the entire product lifecycle.

PADS Pro vs. Xpedition Enterprise

Understanding this relationship is crucial to grasping Siemens’ market strategy. PADS Professional is built on Xpedition technology but serves independent engineers and small teams in a more accessible package. Xpedition is the full enterprise solution.

The fundamental difference? Collaboration and concurrency. Xpedition enables hundreds of engineers to work simultaneously on the same project—one on schematics, another on layout, another on libraries—without conflicts.

Dual-Pillar Simulation Approach

Siemens’ simulation capabilities rest on two specialized foundations:

Xpedition AMS (Analog/Mixed-Signal) — This goes far beyond standard SPICE by supporting VHDL-AMS language, enabling engineers to model and simulate not just electrical components but multiple physics domains (thermal, mechanical, hydraulic) within the same model.

HyperLynx Suite — This represents Siemens’ crown jewel in simulation. HyperLynx isn’t a simple SPICE simulator—it’s a complete analysis and verification platform for high-speed designs.

HyperLynx capabilities include:

- Signal Integrity (SI) and Power Integrity (PI) Analysis — Ensuring high-speed data paths (DDR5, PCIe) will function after physical routing

- Advanced Solvers — 3D Electromagnetic Full-Wave Solvers and Quasi-Static Solvers analyze PCBs as physical 3D objects, predicting Electromagnetic Compatibility (EMC) and Interference (EMI) issues

- Electrical Design Rule Checking (eDRC) — Validates electrical rules (does this trace act like an antenna and radiate EMI?) beyond geometric rules

Siemens positions simulation not as a feature but as a comprehensive platform. The goal isn’t just verifying circuit functionality—it’s guaranteeing that physically manufactured designs will work under all conditions (including worst-case scenarios, layout parasitics, thermal stress, EMI emissions) while meeting all legal compliance standards.

Best For: Enterprise R&D teams in defense, telecommunications, semiconductors, and automotive requiring maximum reliability, advanced physical analysis (SI/PI/EMI/Thermal), and multi-user concurrent design capabilities.

Integrated Platform Innovation: Autodesk Fusion 360

Autodesk created a unique market position by acquiring EAGLE and integrating its Electronic Design Automation (ECAD) capabilities into Fusion 360, their flagship mechanical design platform. This strategy transforms PCB design from an isolated process into an integral part of the complete product development lifecycle.

True ECAD/MCAD Integration

Fusion 360’s core value proposition is genuine ECAD/MCAD integration. While other platforms (Altium, Cadence, KiCad) rely on exporting and synchronizing file formats like STEP, IDF, or IDX, Fusion 360 houses both PCB (ECAD) and product enclosure (MCAD) in the same core data model.

This “eliminates the need for separate software solutions.” When an engineer moves a component on the PCB, they instantly see whether that component’s 3D model interferes with the mechanical enclosure or blocks thermal airflow. This represents revolutionary workflow efficiency for mechatronic-focused teams, especially in consumer electronics, wearables, and IoT devices where mechanical constraints equal electrical constraints in importance.

Design Flow and Simulation Capabilities

Fusion 360’s electronic design process (schematic, layout, library management) builds on EAGLE’s legacy but adds a modern interface and enhanced features. It provides full synchronization between schematic and PCB, Design Rule Checking (DRC), and modern routing modes like “Push and Shove.”

Simulation capabilities follow a dual structure similar to Siemens:

Core Simulation (SPICE) — Fusion 360 Electronics includes an integrated SPICE simulator based on open-source ngspice for circuit schematic validation. This engine fully supports standard analysis types: Operating Point, DC Sweep, AC Sweep, and Transient. Users can simulate with components from ngspice-simulation and ngspice-digital libraries or add custom SPICE models.

Advanced Simulation (Extensions) — Fusion 360’s ECAD/MCAD integration power emerges through physical analysis via extensions:

-

Thermal (Cooling) Simulation — The Cooling extension analyzes heat generated by PCB components, accounting for the board itself and mechanical enclosure as thermal mass. It simulates active cooling solutions like fans, preventing thermal failures.

-

Signal Integrity (SI) — The Signal Integrity extension analyzes impedance matching for high-speed signals during layout. It visually displays signal impedance problems on 2D PCBs with color-coded overlays and provides critical data like signal delay, inductance, and capacitance.

Best For: Mechatronic-focused startups or product companies where PCB must fit flawlessly within mechanical enclosures, requiring integrated thermal management and zero friction between electrical and mechanical teams.

Open Source Power: KiCad Reaches Professional Grade

KiCad has completely shed its “hobby tool” label, evolving into a reliable, completely free EDA platform with capabilities rivaling many paid tools. Today, it’s actively used not just by hobbyists and startups, but by small-to-medium businesses and even larger companies for professional projects.

Design Capabilities

KiCad consists of two main components: Schematic Editor (Eeschema) and PCB Editor (PcbNew). It delivers many features expected from modern EDA tools:

- Powerful “push-and-shove” interactive router

- Support for up to 32 copper layers

- Integrated 3D Viewer for design validation

- Comprehensive Design Rule Checking (DRC)

- Library management leveraging both KiCad’s official community-managed libraries and extensive third-party ecosystems from SnapEDA, Digi-Key, and SparkFun

Simulation Capabilities

KiCad integrates simulation directly into Eeschema, the schematic editor, using a powerful, mature open-source engine.

Engine — KiCad uses the open-source ngspice simulator for simulation.

Workflow — Users draw circuits on schematics, assign SPICE models to components (typically as .MODEL or .SUBCKT definitions), select simulation types (AC, DC, Transient), and analyze results directly within KiCad.

Analysis Types — Through ngspice’s power, KiCad supports basic AC/DC/Transient analyses plus potentially much more advanced analyses like “Electro-Thermal simulation.”

KiCad’s simulation presents an interesting paradox: the underlying ngspice engine is extremely powerful and capable. However, utilizing this power requires more manual effort and deeper SPICE knowledge compared to commercial rivals’ “guided” experiences with thousands of pre-verified models. Setting up complex models (transformers, for example) or debugging SPICE-specific errors like “singular node error” falls entirely on users.

Additionally, older KiCad versions had perceptions that “clean” schematics for simulation couldn’t be identical to “real world” schematics for PCB layout. While KiCad 8 and later versions dramatically improved this integration, managing both PCB export and SPICE netlist generation simultaneously in complex designs may still require careful approaches.

Best For: Individual professionals, consultants, or budget-focused small businesses needing powerful, reliable, modern tools without cost barriers but capable of professional-level multi-layer designs and basic circuit validation.

Other Notable Alternatives

DipTrace targets small-to-medium enterprises seeking “ease of use” and “flexibility.” It features extremely low learning curves and intuitive interfaces. DipTrace includes an integrated SPICE simulator, but its most clever strategy involves offering direct SPICE netlist export to LTSpice—the free, hugely popular simulator engineers already trust. This enables workflows where users draw circuits in DipTrace’s easy interface and analyze them in industry-standard simulators.

EasyEDA is designed specifically for “beginners” and “rapid prototyping”—a browser-based (cloud), free tool. It supports “simple circuit simulations” with SPICE-based engines. EasyEDA’s real purpose emerges from being developed by JLPCB, one of the world’s largest PCB prototype manufacturers. EasyEDA functions less as an independent design tool and more as a “Tool for Manufacturing,” seamlessly funneling users into JLPCB’s production and component supply ecosystem.

Simulation Capabilities: Three Distinct Layers

Electronic circuit simulation isn’t a simple “yes or no” feature. Market tools’ simulation capabilities can be examined across three layers based on purpose and depth:

Layer 1: Baseline SPICE Integration

Tools: KiCad, Fusion 360 (Core Simulation), EasyEDA

Engine: Typically open-source ngspice or similar SPICE engines

Capability: Basic analog, digital, and mixed-signal analyses (Transient, AC, DC)

Purpose: Validating circuit concepts—“Does my filter circuit cut the correct frequency?” or “Does this op-amp circuit amplify signals correctly?”

Limitations: Ready-made model libraries may be limited compared to commercial competitors. Setting up and debugging complex circuits may require deep SPICE knowledge. Typically doesn’t include advanced SI/PI or physical analysis.

Layer 2: Advanced and Integrated SPICE

Tools: Altium Designer, Cadence OrCAD X, DipTrace (with LTSpice)

Engine: Commercially supported, highly optimized, stable engines (PSpice, Altium’s integrated engine)

Capability: Everything in Layer 1 plus statistical and reliability analyses like Monte Carlo, Worst-Case, and Stress/Smoke. The biggest difference? Massive libraries with thousands (35,000+ for PSpice) of verified, managed component models and “guided” setup wizards.

Purpose: Validating PCB schematic reliability and maximizing designer productivity

Limitations: Simulation generally works on “ideal” schematics. While they perform post-layout parasitic extraction, these tools typically have limitations in modeling complex electromagnetic effects like EMI/EMC.

Layer 3: Multi-Domain and Physical Analysis

Tools: Siemens Xpedition (AMS + HyperLynx), Cadence (PSpice + SLPS/MATLAB), Fusion 360 (with Extensions)

Engine: Not just SPICE—includes VHDL-AMS (multi-physics modeling), EM Solvers (Full-Wave), and co-simulation engines (SLPS)

Capability: This layer simulates circuits’ physical reality:

- Cadence: Bridges electrical (PSpice) and Control/Algorithm (Simulink) worlds

- Siemens: Unifies Electrical (AMS), Mechanical/Thermal (VHDL-AMS), and Electromagnetic (HyperLynx) worlds

- Fusion 360: Combines Electrical (SPICE), Mechanical/Thermal (Cooling Extension), and Signal Integrity (SI Extension) worlds

Purpose: Physical product validation, system-level analysis, and compliance with legal standards (EMI/EMC, thermal)

Comprehensive Feature Comparison

| Platform | Core Simulation | Advanced SPICE | SI/PI | Thermal | Multi-Domain |

|---|---|---|---|---|---|

| Altium Designer | Integrated Multi-format SPICE | Yes | Yes (built-in tools) | Limited (3rd party plugins) | No (electrical focus) |

| Cadence OrCAD/Allegro | PSpice | Yes (Advanced Analysis) | Yes (Allegro SI) | Yes (Allegro) | Yes (SLPS with MATLAB/Simulink) |

| Siemens Xpedition/PADS | Xpedition AMS (SPICE + VHDL-AMS) | Yes | Yes (HyperLynx SI/PI) | Yes (HyperLynx Thermal) | Yes (Native VHDL-AMS and HyperLynx EM Solvers) |

| Fusion 360 | ngspice | No (basic SPICE) | Yes (with SI Extension) | Yes (with Cooling Extension) | Yes (mechanical & thermal integration) |

| KiCad | ngspice | Potential (engine supports, interface limited) | No (requires 3rd party tools) | Potential (Electro-Thermal) | No (no native support) |

Strategic Comparison: Enterprise vs. Integrated vs. Open Source

| Feature | Altium Designer | Cadence (OrCAD/Allegro) | Siemens (PADS/Xpedition) |

|---|---|---|---|

| Core Philosophy | Unified Productivity Platform | Scalable System Modeling | Enterprise Digital Twin & Physical Analysis |

| Main Simulator | Integrated Multi-Format SPICE | PSpice (Native Integration) | Xpedition AMS (SPICE + VHDL-AMS) |

| Advanced Platform | Built-in SI tools | Allegro SI / PSpice Advanced | HyperLynx Suite (SI/PI/EMI/eDRC) |

| Multi-Domain | Limited (electrical only) | SLPS with MATLAB/Simulink | Native VHDL-AMS (Multi-Physics) |

| Enterprise Scaling | Altium 365 Platform | OrCAD X to Allegro Path | PADS Pro to Xpedition Path |

Beyond Features: Strategic Factors That Matter

ECAD/MCAD Integration Philosophy

Modern electronics product design requires tight collaboration between mechanical and electronic teams. How this collaboration is managed reveals fundamental philosophical differences:

Fusion 360 (“Native”) — Offers the market’s only true native integration. ECAD and MCAD share the same database, providing the smoothest workflow for mechatronic design.

Altium, Cadence, Siemens (“Linked”) — These enterprise tools rely on “export/import” methods through standardized file formats like STEP, IDF, or IDX. This represents a powerful, decades-proven workflow, but it’s “linked” rather than “unified.”

KiCad (“Plugin”) — Features a 3D Viewer and increasingly better integration with open-source MCAD tools like FreeCAD through community-developed plugins. This works at professional levels but requires manual setup and synchronization effort.

Learning Curve and the Power Paradox

EDA tool learning curves directly impact productivity. However, “ease of use” often inversely relates to “power.”

Market reports contain seemingly contradictory statements about Altium being both “intuitive” and having a “steep learning curve.” Similarly, KiCad is described as both “user-friendly” and (especially for beginners) “overwhelming.” This isn’t contradiction—it’s the “Power Paradox”:

Altium — Has an extremely polished and intuitive interface for entry-level tasks. However, beneath this surface lies complexity of advanced features like signal integrity, constraint management, or multi-board projects. The learning curve steepens dramatically when transitioning from “basic” to “advanced.”

KiCad — Its interface is less polished and simpler than commercial rivals. “Overwhelming” aspects typically stem from EDA’s inherent complexity, not from dozens of nested enterprise features like Altium. KiCad’s learning curve is more linear.

Enterprise Tools (Cadence/Siemens) — Traditionally known for the steepest learning curves. This stems from expecting enterprise-level constraint management and complex workflows from the start.

Ecosystem and Collaboration

How teams work together represents another critical strategic differentiator:

Enterprise (Platform) Approach — Altium (Altium 365), Cadence (Cloud), and Siemens (Xpedition Enterprise) now sell “platforms,” not just “tools.” These platforms offer cloud-based centralized library management, version control, and “real-time collaboration.” Xpedition’s core advantage over PADS Pro is precisely this “concurrency”—multi-user functionality.

Open Source (File) Approach — KiCad is inherently “offline” and “file-based.” Collaboration features aren’t “built-in.” However, KiCad’s text-based file formats work perfectly with modern Version Control Systems (VCS) like Git. This provides powerful advantages for modern teams applying software development methodologies (agile) to hardware development.

Strategic Recommendations: Choosing by Engineering Persona

There’s no single “best” PCB design software—only the “most suitable” for specific tasks, teams, and products. Analysis reveals these strategic recommendations for different engineering personas:

Persona 1: Enterprise R&D (Defense, Telecom, Semiconductor, Automotive)

Need: Maximum reliability, most advanced physical analysis (SI/PI/EMI/Thermal), high-density (HDI) designs with thousands of components, and large concurrent teams

Recommendation: Siemens Xpedition (with HyperLynx) or Cadence Allegro (with PSpice and SLPS)

Rationale: This persona’s priority isn’t “rapid productivity” or “ease of use”—it’s guaranteeing “first-time-right” products meeting the most demanding compliance and physical standards. Siemens excels at deepest physical and multi-domain analysis (digital twin). Cadence leads in system modeling (Simulink integration) and highest-density designs.

Persona 2: Professional Teams (Consumer Electronics, SMBs, IoT)

Need: Fast product development cycles, powerful yet user-friendly simulation/validation suite, robust library and supply chain management, efficient workflow

Recommendation: Altium Designer

Rationale: Altium’s “unified” philosophy combines schematic, simulation (SPICE), layout, and BOM management in one fluid interface, maximizing productivity these teams require.

Persona 3: Mechatronic-Focused Startup or Product Company

Need: Perfect PCB-to-mechanical-enclosure fit, integrated thermal management, rapid prototyping with zero friction between electrical and mechanical teams

Recommendation: Autodesk Fusion 360

Rationale: For this persona, ECAD doesn’t need to be “best”—ECAD and MCAD need to work together perfectly. Fusion 360’s native, integrated ECAD/MCAD workflow and integrated thermal/SI simulation extensions are strategically superior to all other solutions’ “export/import” methods.

Persona 4: Individual Professional, Consultant, or Budget-Focused SMB

Need: No cost barriers, yet capable of professional-level (multi-layer, basic high-speed) designs and basic circuit validation (SPICE) with powerful, reliable, modern tools

Recommendation: KiCad

Rationale: KiCad is now “professionally viable.” Features like 32-layer support, push-and-shove routing, and the powerful ngspice engine are more than sufficient for the vast majority of professional projects. Its open-source nature combined with Git (VCS) provides modern, flexible workflows.

The Bottom Line

The EDA market’s evolution reflects broader trends in electronics engineering: increasing design complexity, accelerating product cycles, and growing demand for first-time-right designs. The right tool choice depends less on which platform has the most features and more on which platform aligns with your team’s workflow, project complexity, and strategic priorities.

For enterprise teams where failure isn’t an option, invest in Siemens or Cadence’s comprehensive validation platforms. For professional teams prioritizing productivity and unified workflows, Altium delivers exceptional value. For mechatronic product development, Fusion 360’s integrated approach eliminates traditional ECAD/MCAD friction. And for individuals or budget-conscious teams, KiCad has matured into a genuinely professional-grade solution.

The $28.75 billion question isn’t “What’s the best PCB design software?"—it’s “What’s the best PCB design software for your specific engineering challenge?” Answer that question strategically, and you’ll choose a tool that accelerates rather than hinders your path to market.

Sources: Industry market analysis reports, EDA vendor technical documentation, and professional engineering community assessments compiled for 2025 technology review.